Crafted for the Dedicated: Off-Road Enthusiasts, Professionals, and Serious DIYers

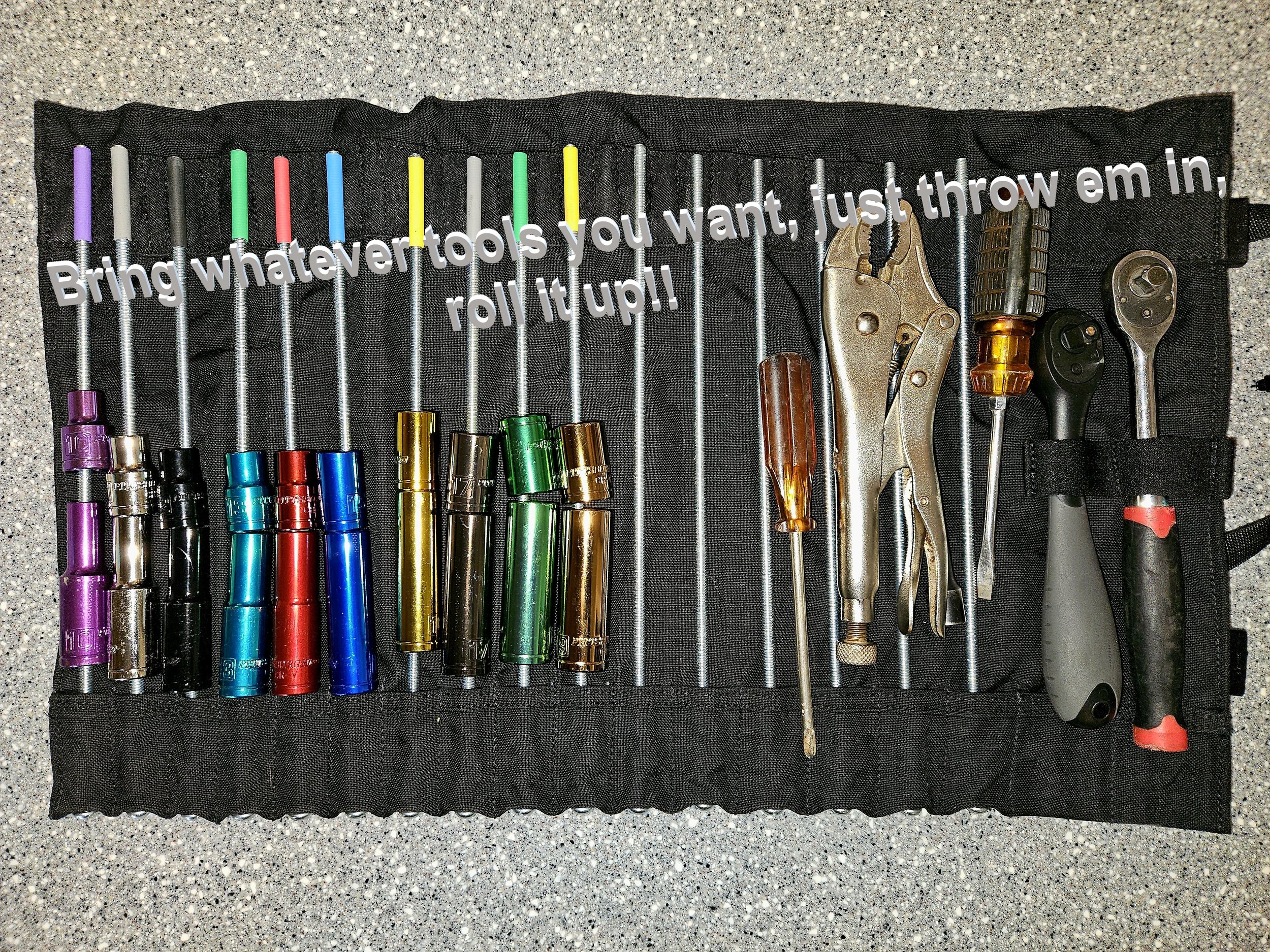

All your most used sockets in one convenient location, neatly organized by size, rather than brand or tricky shapes

Features

Organize sockets by size. When wrenching, size matters! Not brand, not shape, not direction. Throw it on the rod and be done with it!

Any socket with a hole in the middle will work.

Color code the rods if desired to match existing socket color, use tape on colorless ones.

Designed for 10mm to 25mm. Other sizes are seldom used, and just get in the way. (SAE works fine too, organize however you wish)

Rollable to fit in your toolbox, and carry without worrying about the case falling open, and giving yourself another project: hide and seek with sockets.

Magnets to keep things mostly in line.

Designed to be bumpable, droppable, and movable, because things get crazy when you're wrenching!

Strong - Double ply 1000 Denier Cordura Nylon: strongest fabric available without adding Kevlar.

Basic - Easy to source materials, so replacements can be bought at a local hardware store.

Cleanable - If things get too crazy, it’s just steel and nylon, get out a garden hose and some degreaser!

I personally prefer to buy things Made In The USA, where possible, and providing jobs as a result!

The Sockettier is pretty basic. We can make additions later, but yeah, it's basic. Here's where I source my materials:

Manufactured by Atlas46 out of Fenton, Missouri

1000 Denier Cordura Nylon - Purchased from New York Tarp & Company out of NY

Threaded Rod - Purchased from Grainger out of IL

Coupler - Purchased from Tanner Bolt out of NY

Machine screw - Purchased from Tanner Bolt out of NY

Labels - Custom printed in AZ

Neodymium magnets - Purchased from Total Element Magnets in CO

Prototypes

The initial premise was to make this thing indestructible. I can't tell you how many socket organizers I've destroyed over the years because they were made out of cheap plastic!! We only want to sell you one, and hopefully never wear it out.

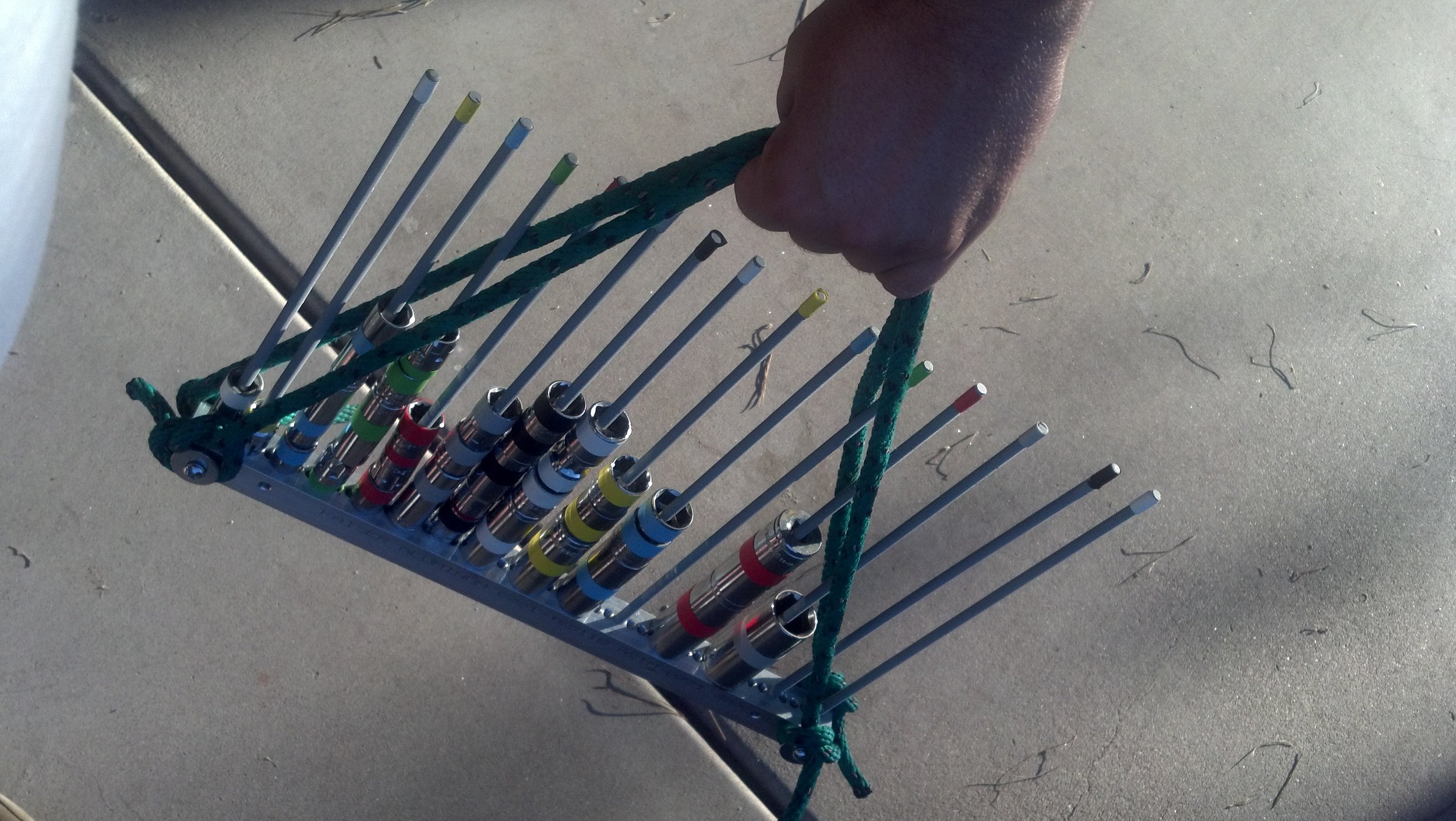

v0.01 - Very first prototype. Yep, rods work, need different spacing for large sockets

v0.02 - Solid steel cylinder, tapped for rod, cut to different widths to accommodate different sized sockets. Way too hard to produce.

v0.03 - Wood is sustainable, right? Too bulky, looked dumb

v0.04 - Back to metal, definitely. Let's cut some stuff up and see what works!

v0.05 - Metal bar, tapped at regular intervals, metal sides, with handle.

v0.06 - How about a barebones version? Nope. Rope got tangled. Big drop hazard.

v0.07 - Ok, let's make it out of aluminum, have hinges, so the handle keeps the sides closed! Sooo close!!

v0.08 - Ok, how about fabric? Oh my. Looks like a purse! Burn it with FIRE!!

v0.09 - What we thought would be the production version. All pieces mass producible. Nope. Scratched the heck out of everything, Wasn't portable enough, and loud during vibrational driving.

v.10 - Uhhh, hey babe? You know how to sew, right?? BAM. That's it!! Magnets behind the rod, nothing needs to be machined!!

v0.11 - Slightly more professional, tweaked width. Time to go big or go home!

v0.5 - Mmmm, Got some professional sewers to make some protoypes.

v1.0 - First production run of 50 units from Atlas46!

The Guys

We've been friends since 1999, met at work in Phoenix, and consider each other family.

Random stuff we've built/done:

Light bar for Jose's FJ, featuring KC DayLighters

Rear wheel motorcycle stand

Equalateral triangle welding table

Mobile workbench with fold away mount for miter saw

Sand table for working with kids

Mobile bandsaw mount that doubles as a welding cart

Metal brake

Double gimbal camera mount

Truck leaf spring shackles

Head gasket on Jose's 99 neon RT

Matt works in Phoenix as a SQL Server developer, doing everything from data transfer, analysis, to reporting, and data warehouse design

Jose works in Mesa as an IT Manager, doing everything from server infrastructure to databases to desktops and networking